- info@aynurenerji.com

- +90 533 610 20 97

- Maltepe / İSTANBUL

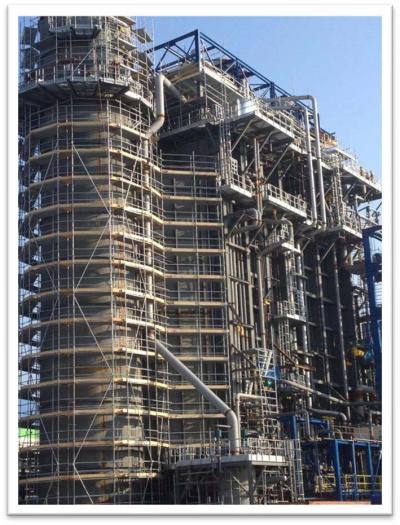

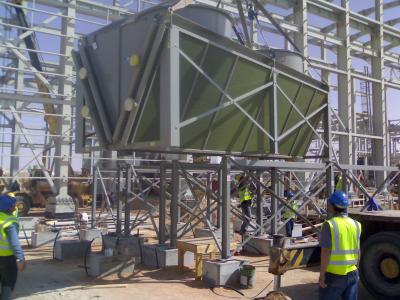

Aynur Enerji & Insaat has proven its know-how obtained through the projects undertaken with its experienced white and blue collar workers within it also with the reference projects. Aynur Enerji & Insaat reassures all the employers in its field that they can easily work together in their electromechanical installation projects of any scale and difficulty with its present employees and experience accumulated for a long time.

Aynur Enerji & Insaat coorporate culture and technical library created with its experiences accumulated in many years allow for meeting the expectations of the contracting companies without deviating from occupational safety, quality, budget and work plans.

Aynur Enerji & Insaat does not give rise to the shareholders living surprises in the fundamental aspects of the project throughout the project thanks to its fiduciary relationship with the contracting companies. Internally-created formats of planning and reporting allow for complete monitoring at any stage of the project.

To sum up the sectors in which Aynur Enerji & Insaat has specialized in electromechanical installation:

• Combined Cycle Power Plant (CCPP)

• Simple Cycle Power Plant (SCPP)

• Coal Power Plant

Aynur Enerji & Insaat in the Power plants, can adequately perform all the electromechanical installations of the items such as;

Electromechanical installation of GAS TURBINE and AUXİLLARY systems is as follows:

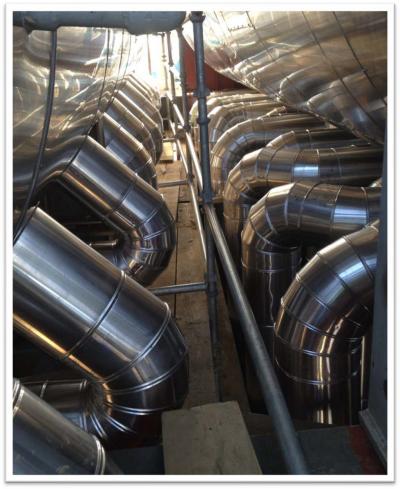

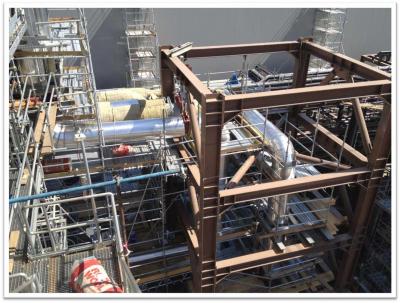

Air Intake unit, which is a part of gas turbines in power plants, installation, filter installation and replacement, air duct assembly connected to gas turbine are performed within the scope of turnkey plant installation.

Electromechanical installation of STEAM TURBINE and auxiliary equipment is as follows:

Gas turbines as electricity and I&C assembly work:

GENERETOR ELECTRICAL and I&C assembly works :