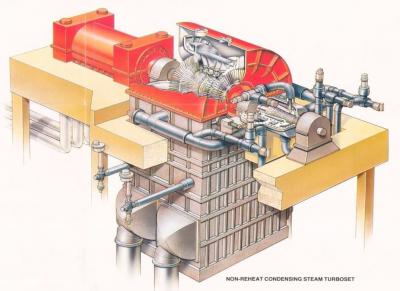

Steam Turbine Maintenance

Aynur Enerji

Steam Turbine Maintenance

- Disassembly and assembly of high pressure, medium pressure and low pressure rotors,

- Maintenance of high pressure, medium pressure and low pressure stages,

- Main lubrication gear unit maintenance,

- Disassembly and maintenance of steam sealing bodies,

- Turbine outer and inner casing axial and radial wedge control, making it operational,

- Turbine bearings control, NDTs and maintenance,

- Application of NDT to rotor blades,

- Diameter control of gland vapor sealing system labyrinths and replacement if necessary,

- Checking the bearing oil sealing labyrinths and replacing them with new ones if necessary,

- Testing and assembling of gland and turbine casings; Checking and joining between half of the blueprint and if necessary,

- Bed Blueprint tests and acclimatization, shim settings,

- Performing and evaluating rotor lead test, making radial and axial adjustments, assembling, keeping radial and axial stator-rotor clearance protocol values,

- Disassembly, maintenance, compensator controls, installation of crossover pipe,

- Inspection and maintenance of lubricating oil and lifting oil unit,

- Main oil tank maintenance,

- Turbine oil change and filtration of oil with mobile filtration unit,

- Maintenance of fixed and movable wings,

- Turbine coupling adjustment,

- Commissioning,

- Troubleshooting vibration problems

- Balancing on the rotor site,

- Sandblasting of rotor and movable fixed blades.